Before conducting a restraint system inspection, auto repair professionals must prepare thoroughly by reviewing vehicle history, gathering functional tools, and providing staff with relevant resources. This process ensures comprehensive evaluation of airbags, seatbelts, and impact mechanisms against manufacturer standards and regulations. Specialized tools like load sensors, strain gauges, and precision calipers are vital for accurate measurements and testing, while hand tools, jack stands, and reliable lifts aid in safe frame straightening. These preparations are critical for identifying potential issues and facilitating tailored solutions, making restraint system inspection a key component of quality auto repair services.

“Ensure comprehensive and accurate documentation with these essential steps for crafting a Restraint System Inspection Report. From preparation to submission, this guide navigates the process efficiently. Begin by understanding the scope and gathering necessary tools, then conduct a meticulous examination of the restraint system’s components. Document findings, from physical observations to performance testing, while adhering to safety standards. Finally, compile a structured report detailing recommendations and follow-up actions for a seamless inspection process.”

- Preparing for the Inspection

- – Understanding the scope and objectives of the inspection

- – Gathering necessary tools and equipment

Preparing for the Inspection

Before conducting a restraint system inspection, thorough preparation is key to ensuring accuracy and efficiency. Begin by reviewing the vehicle’s service history and any previous inspection reports, focusing on the records related to the restraint system, including airbags and seatbelts. This step is vital in understanding the system’s historical performance and potential areas of concern.

Next, gather all necessary tools and equipment, such as specialized diagnostic scanners for airbag modules and a comprehensive toolkit for physical inspections. Verify that each tool is functional and up-to-date to facilitate a seamless process. Additionally, inform the car body shop or vehicle repair staff about the upcoming inspection, ensuring they have access to the vehicle and any relevant manuals or specifications. This preparation phase sets the stage for a comprehensive restraint system evaluation.

– Understanding the scope and objectives of the inspection

A thorough understanding of the scope and objectives of a restraint system inspection is paramount for accurate documentation. This involves assessing the condition and functionality of the vehicle’s safety equipment, including airbags, seatbelts, and impact-activation mechanisms. The primary objective is to ensure that these critical systems are in compliance with manufacturer standards and regulatory requirements, thereby safeguarding occupants during accidents.

During such inspections, technicians must consider various aspects, from visual examinations for signs of wear and tear to functional tests to verify proper deployment. This process is vital not only for individual vehicle owners but also for automotive collision repair specialists who often handle car body restoration, ensuring that every component, down to the smallest detail, is in optimal condition.

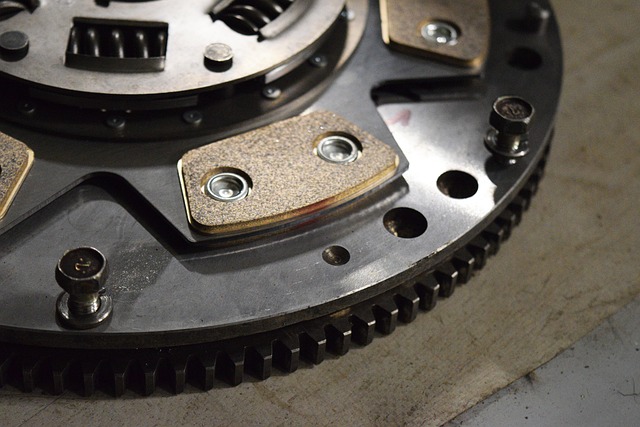

– Gathering necessary tools and equipment

Before beginning a restraint system inspection, it’s crucial to gather all necessary tools and equipment to ensure a thorough evaluation. This includes specialized tools designed for measuring and testing the integrity of the vehicle’s safety systems, such as load sensors, strain gauges, and precision calipers. Additionally, auto repair professionals should have access to a comprehensive set of hand tools, jack stands, and a reliable lift system for safe and accurate frame straightening where needed.

The right equipment facilitates precise measurements and helps identify potential issues with the restraint system, including airbags, seatbelts, and crash-test ratings. By utilizing these tools effectively, auto bodywork experts can provide detailed insights into the overall safety of a vehicle, ultimately enabling them to offer tailored solutions for any deficiencies discovered during the inspection process—a key aspect of quality auto repair services.

Concluding your restraint system inspection involves meticulously documenting every detail, from visual observations to functional tests. By following these structured steps, you ensure a comprehensive record that adheres to industry standards and regulations, ultimately enhancing safety measures for all concerned. Remember, accurate documentation is key to effective communication and future reference during maintenance or regulatory audits.