Advanced digital tools have transformed restraint system inspections in vehicles, improving accuracy and efficiency compared to traditional manual methods. These technologies include 3D scanning, CAD, and specialized software applications that enable detailed analysis of mechanisms like airbags and seatbelts. The result is enhanced safety, faster turnaround times, reduced costs, and improved quality control in car body shop services. Digital solutions offer comprehensive assessments, detect subtle defects, ensure optimal component function, and provide valuable data for trend analysis, ultimately streamlining auto glass replacement and bodywork repairs.

In today’s digital era, the realm of restraint system inspection has undergone a profound metamorphosis. The digital revolution has ushered in innovative tools that enhance accuracy and efficiency, ensuring safety across various industries. This article explores how advanced technology is transforming restraint inspections. From enhanced precision to data-driven insights, these tools provide comprehensive coverage, enabling professionals to make informed decisions. Discover the game-changing impact of digital solutions on maintaining robust restraint systems.

- Digital Revolution: Transforming Restraint Inspections

- Enhanced Precision: Tools for Comprehensive Coverage

- Data-Driven Accuracy: Ensuring Safety Through Tech

Digital Revolution: Transforming Restraint Inspections

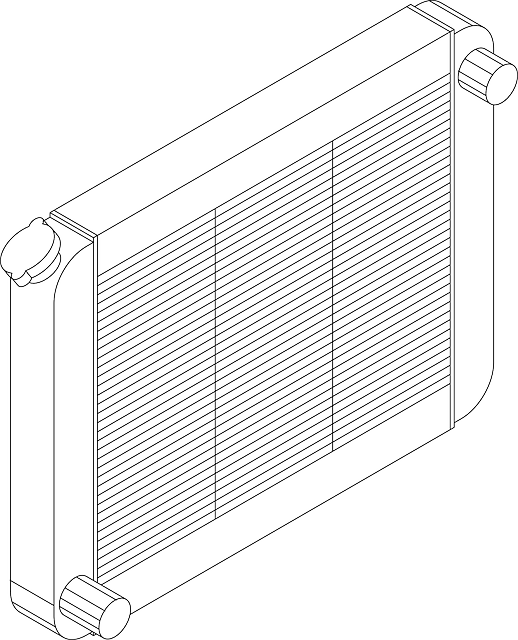

The digital revolution has brought about a significant transformation in the way restraint system inspections are conducted, enhancing accuracy and efficiency. Traditional inspection methods relied heavily on manual checks and human observation, which could be time-consuming and prone to errors. Digital tools, however, offer a game-changing approach. With advanced technologies like 3D scanning, computer-aided design (CAD), and specialized software applications, car body shop services can now streamline the entire inspection process.

These digital solutions enable detailed analysis of restraint mechanisms, providing an in-depth look at their condition. For instance, 3D scanning technology can capture precise measurements and identify even the subtlest imperfections or misalignments. This level of precision is invaluable for ensuring the safety and integrity of vehicle components, particularly in complex systems like airbags and seatbelts. As a result, car paint repair and body shop services benefit from faster turnaround times, reduced costs, and improved overall quality control during restraint system inspections.

Enhanced Precision: Tools for Comprehensive Coverage

Digital tools have significantly upped the ante when it comes to restraint system inspection accuracy. Gone are the days of manual, time-consuming checks, replaced by advanced technologies that offer comprehensive and precise assessments. These tools can detect even the subtlest defects or wear and tear in vehicle restraint systems, ensuring every component is functioning optimally.

By leveraging digital solutions, fleet repair services and collision repair services can achieve a level of thoroughness previously unattainable. This translates to enhanced safety for drivers and passengers, as well as cost savings through proactive maintenance. Comprehensive coverage provided by these tools means no stone is left unturned during inspections, leading to more reliable vehicle restoration and improved overall performance.

Data-Driven Accuracy: Ensuring Safety Through Tech

In today’s digital era, the integration of advanced tools significantly enhances the accuracy and efficiency of restraint system inspections in vehicles. These data-driven solutions enable auto repair shops to identify potential issues with greater precision, ensuring the safety of every vehicle they service. By leveraging technology, technicians can perform more thorough checks on various components like seatbelts, airbags, and impact zones, minimizing the risk of human error.

Digital tools offer a level of consistency that is hard to replicate manually. They provide detailed records, allowing for trend analysis and data comparison over time. This information is invaluable for identifying common problems specific to different vehicle models or age groups. Moreover, these systems can be integrated into existing workflows, making auto glass replacement and other vehicle bodywork repairs more streamlined, efficient, and ultimately, safer.

The digital transformation of restraint system inspections offers a new era of precision and safety. By leveraging advanced tools, inspectors can achieve comprehensive coverage, ensuring every component is meticulously assessed. This data-driven approach not only enhances accuracy but also plays a vital role in maintaining the highest safety standards within the automotive industry. Embracing these technological advancements is a game-changer, revolutionizing how we inspect and ensure the integrity of restraint systems.